Granite is one of the most popular natural stones used in various construction and decorative applications around the world. China, as one of the largest producers and exporters of granite, has a robust industry dedicated to quarrying and processing this durable and attractive material. This article explores the processes involved in quarrying and preparing Chinese granite for commercial use.

Quarrying Process

- Site Selection: The first step in the quarrying process is locating a quarry site with a significant deposit of quality granite. Geologists perform site surveys to determine the size, depth, and quality of the granite deposit.

- Clearing and Preparation: Once a site is chosen, the surface is cleared of vegetation and topsoil to expose the underlying rock. This preparation involves removing any overburden using heavy machinery.

- Drilling: The next step involves drilling holes into the granite bedrock. The pattern and depth of the holes are carefully planned to ensure the blocks of granite are the correct size for processing.

- Blasting: Explosives are placed in the drilled holes to break the granite into manageable pieces. This process must be meticulously controlled to prevent damage to the granite blocks.

- Block Lifting: The large granite blocks are then cut from the bedrock using diamond wire saws or jet piercing. These blocks are lifted from the bed using cranes and other heavy machinery and transported to the processing plants.

Processing Techniques

- Sawing: At the processing plant, the large blocks are sawn into slabs or tiles depending on the intended use. This is typically done with a gang saw or a wire saw that uses high-grade diamond-tipped blades to ensure precision cutting.

- Polishing: Once the granite is sawn into slabs, it is polished to achieve a high-gloss finish. The polishing process involves progressively finer abrasives until a shiny surface is achieved.

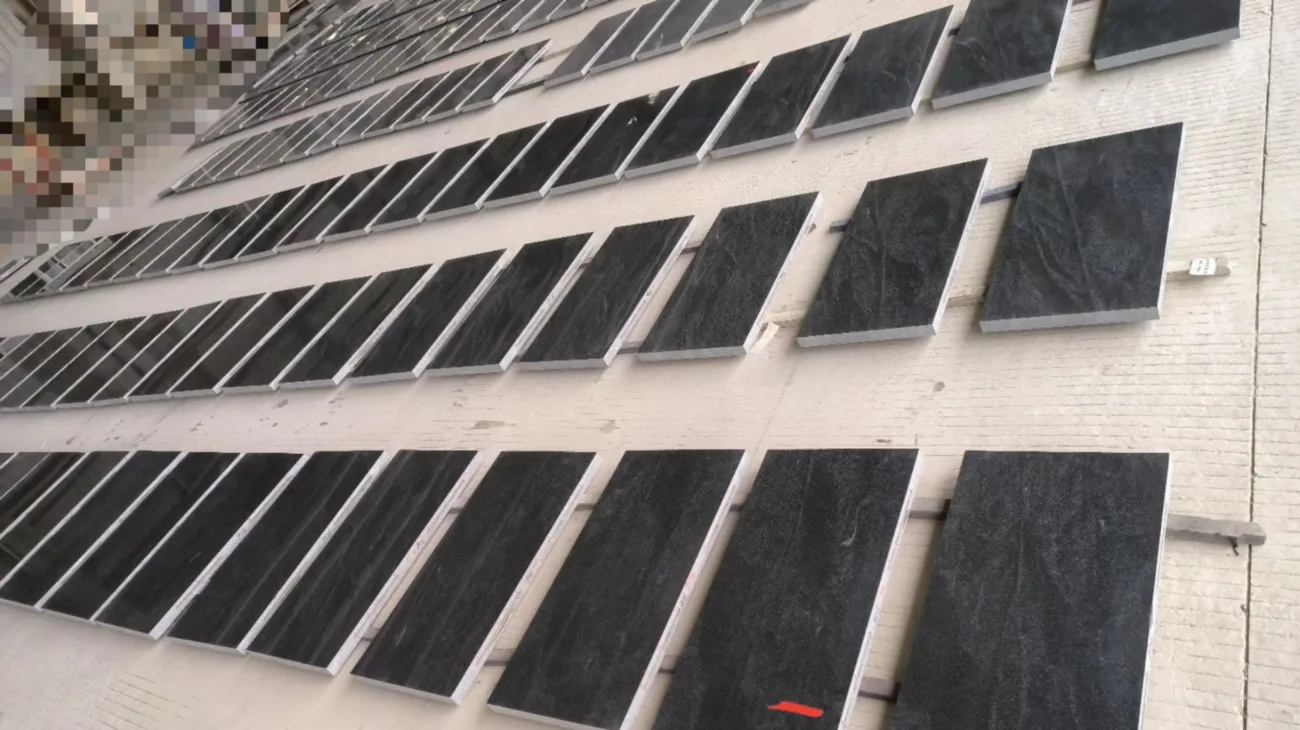

- Calibration and Sizing: After polishing, the slabs are calibrated to ensure they are uniform in thickness and sized according to specifications. This step is crucial for the quality assurance of granite tiles and countertops.

- Edge Cutting and Finishing: For products like countertops, additional steps include cutting the slabs to final dimensions and shaping the edges. Edge profiles may be square, rounded, or beveled based on the design requirements.

- Quality Inspection: Throughout the processing stages, quality control is critical. Each slab or tile is inspected for cracks, blemishes, and uniformity in color and texture. Only those that meet strict quality standards are approved for export or domestic sale.

Applications and Uses

Chinese granite is used globally in numerous applications due to its durability and aesthetic appeal. Common uses include:

- Flooring and Wall Tiles: Its resistance to abrasion and weathering makes it ideal for both interior and exterior applications.

- Countertops: Granite’s heat resistance and easy-to-clean surface make it popular for kitchen and bathroom countertops.

- Monuments and Sculptures: Granite’s durability and ability to withstand environmental factors make it a preferred choice for outdoor sculptures and monuments.

Conclusion

The process of quarrying and processing granite in China is a testament to the country’s ability to blend traditional craftsmanship with modern technology. This ensures that the granite not only meets the aesthetic and functional needs of today’s construction standards but also stands the test of time. As the demand for high-quality natural stone continues to grow globally, China’s granite industry is well-positioned to meet these needs efficiently and sustainably.